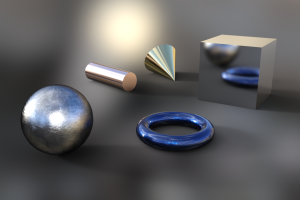

Für einen glänzenden Auftritt

Galvanische Oberflächen

Edelmetalle verleihen einem Produkt eine edle Erscheinung und/oder verbessern die technischen Eigenschaften. Sie werden in Schichtstärken von 0,1 μm (= 1/10000mm) bis zu mehreren μm beschichtet. Die Schichtdicken der aufgebrachten Zwischenschichten (Kupfer, Nickel, Weißbronze) betragen meist mehrere μm und dienen zur Verbesserung der Korrosionseigenschaften und zur Glanzbildung.

Folgende Metalle werden abgeschieden:

Edelmetalle

- Gold

- Palladium

- Platin

- Ruthenium

- Silber

Weitere Metalle

- Kupfer

- Nickel

- Halbglanznickel

- Niphos

Sonstige Bearbeitungen und Oberflächen

Galvanisieren – Färben – Lackieren

Die Palette der Bearbeitungen geht über die Abscheidung reiner Metalle hinaus. Hierdurch können besondere Effekte erzeugt werden.

- Metallfärbung gibt neuen Oberflächen einen antiken Charakter

- Mattieren bricht den metallischen Glanz und verleiht den Oberflächen eine leicht strukturierte, seidig matte Erscheinung

- Halbglanznickel

- Lackierung schützt Oberflächen und Artikel. Lack verbessert die Korrosionseigenschaften und ermöglicht Spezialeffekte

Mechanische Vorbehandlung

Herstellungs- und Formprozesse der metallischen Werkstoffe führen zu chemisch inaktiven und /oder stumpfen Oberflächen.

- Um das Endziel einer hochwertigen Edelmetalloberfläche zu erreichen, müssen die Werkstücke vor der galvanischen Bearbeitung geschliffen und poliert werden. Chemisch passive und korrodierte Schichten werden ebenso wie Grat und Formnähte abgetragen.

- Leichte Unebenheiten in der Oberfläche werden beseitigt, indem das Werkstück zunächst mit einer dicken Kupferschicht versehen wird. Hieraus werden durch Polieren die letzten kleineren Unebenheiten beseitigt.

Lackierung

Wünschen Sie eine dekorative Vergoldung, die einer starken Beanspruchung ausgesetzt wird oder einen besonderen optischen Effekt? Dann überziehen wir Ihre Teile mit Klarlack- oder Effektlackschichten.